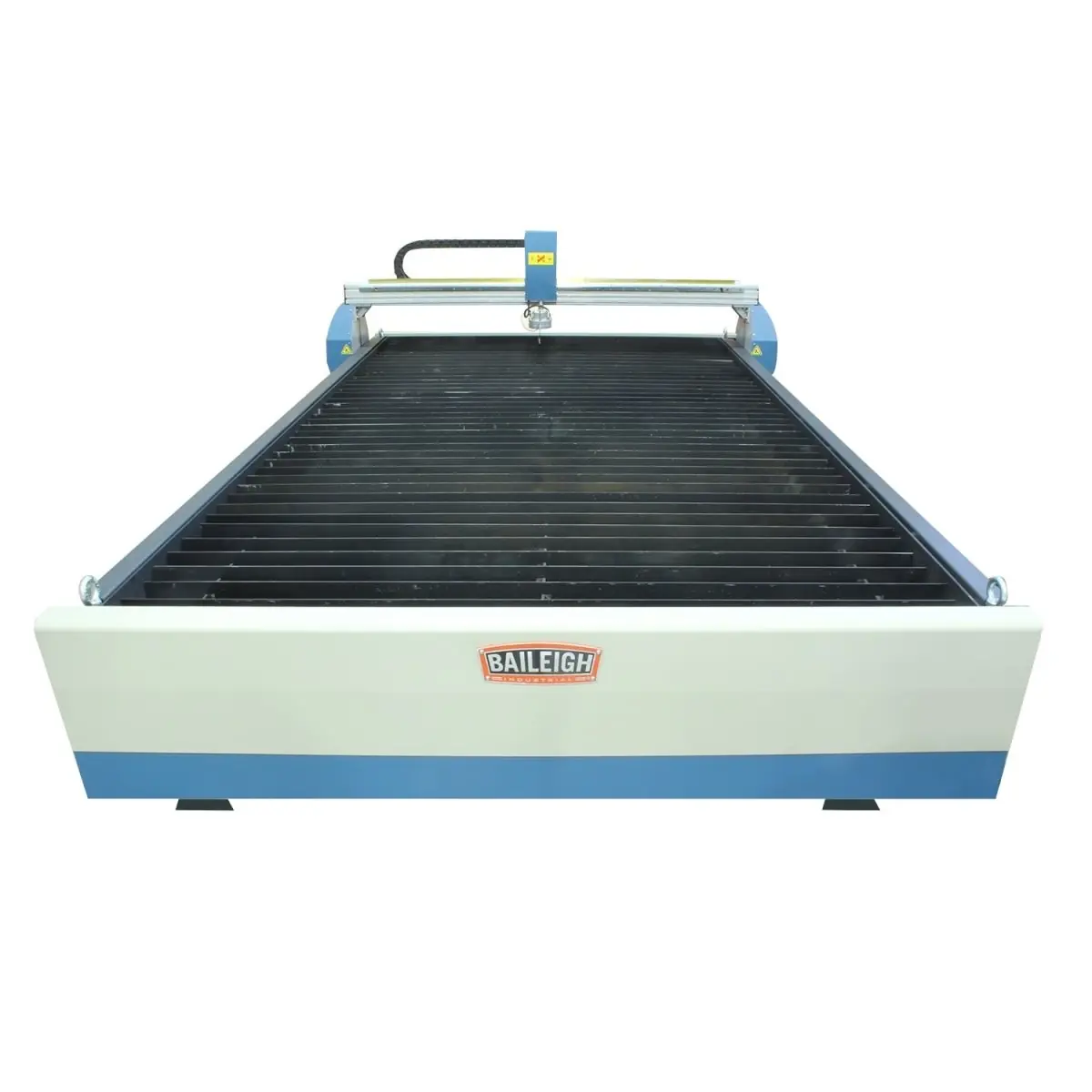

The WJ-85CNC water jet from Baileigh Industrial offers excellent work table accessibility on a machine built for the rigors of waterjet cutting.

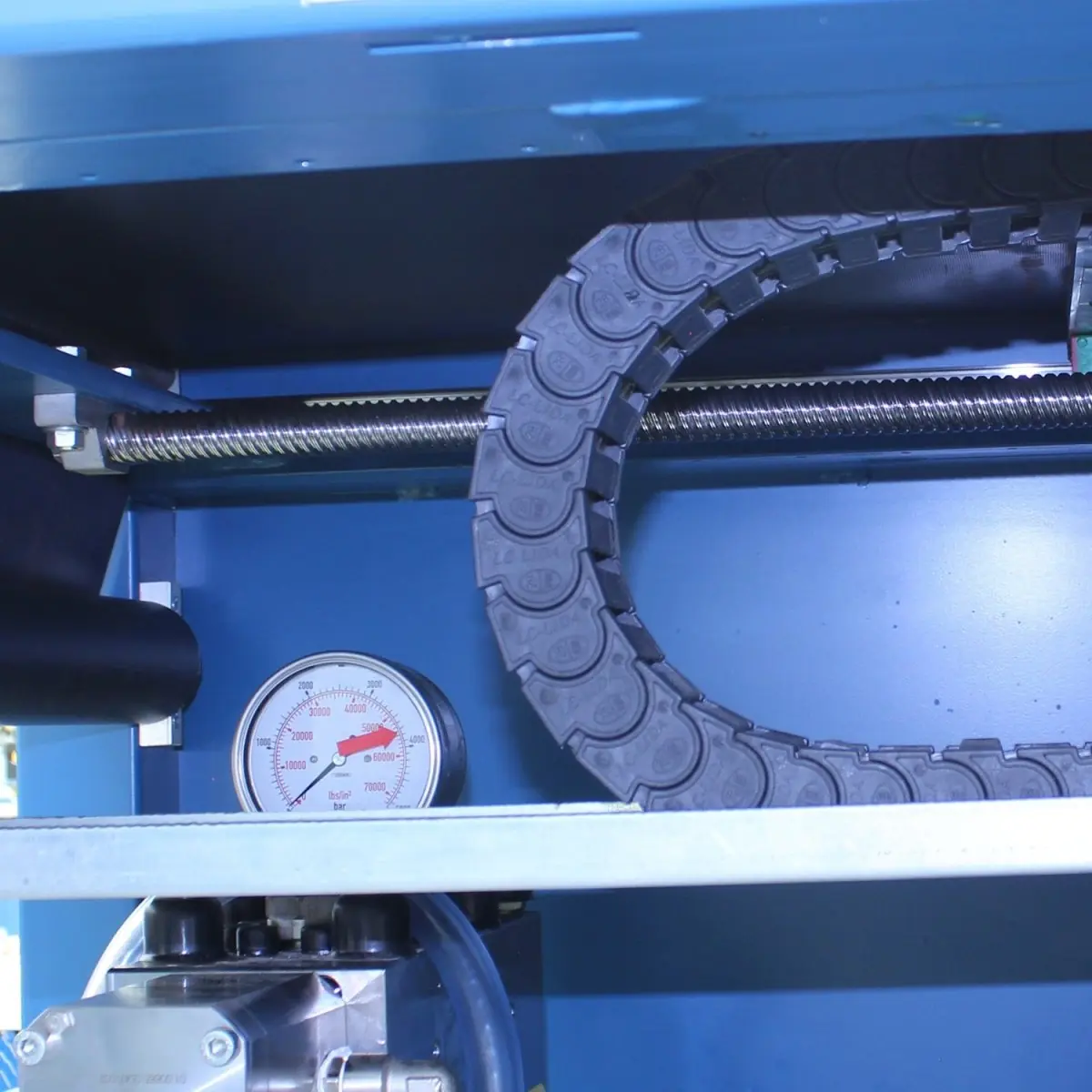

The cutting table and framework of the WJ-85CNC is laser cut and interlocked, then welded for strength and rigidity to ensure accuracy during the cutting process. The design is a cantilever design that allows for much easier material loading and unloading. This CNC water jet cutting machine also offers smoother action on the axis with exclusion of moving parts. All axis ride on precision balls screws with square slide ways. All slide ways are covered and protected from water for long life.

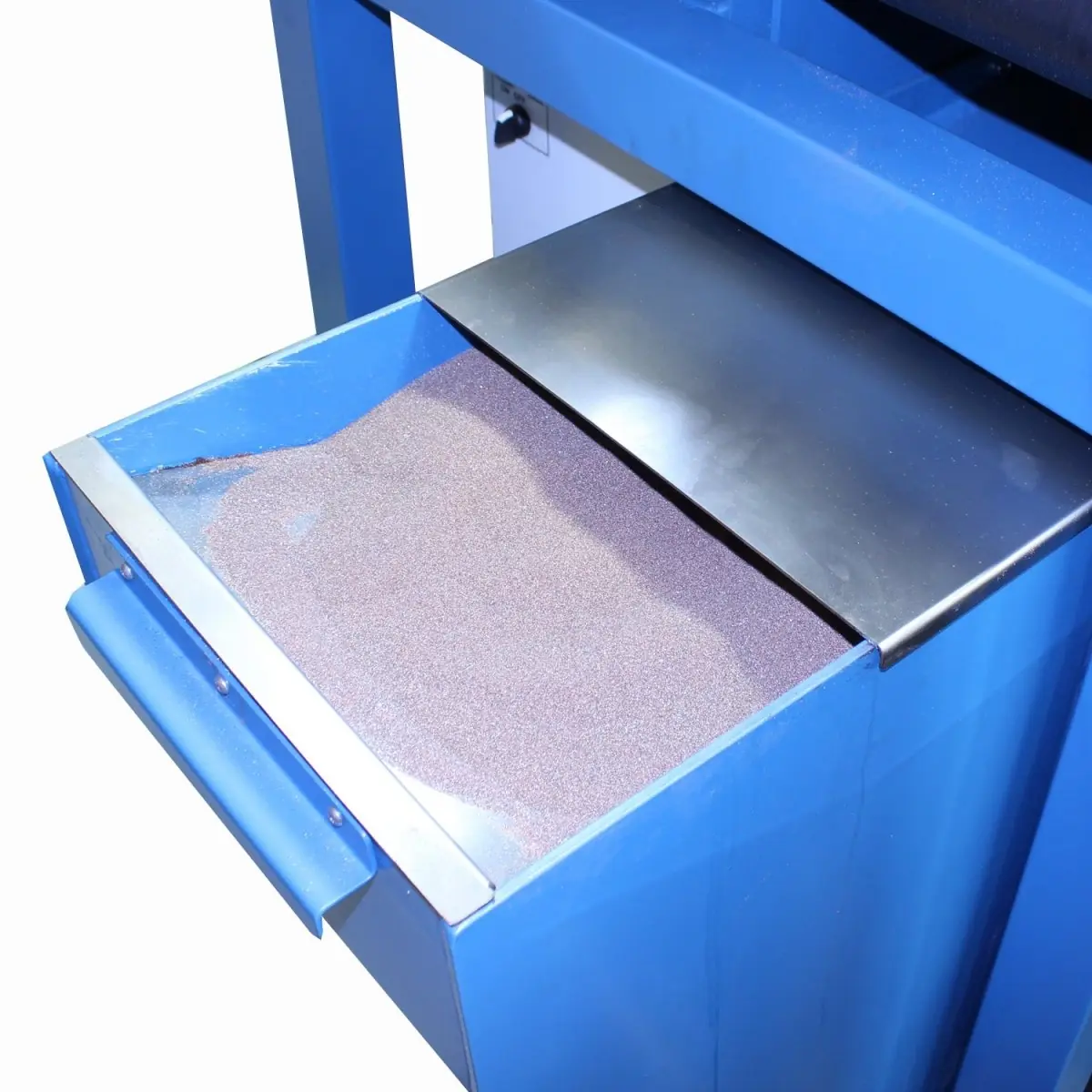

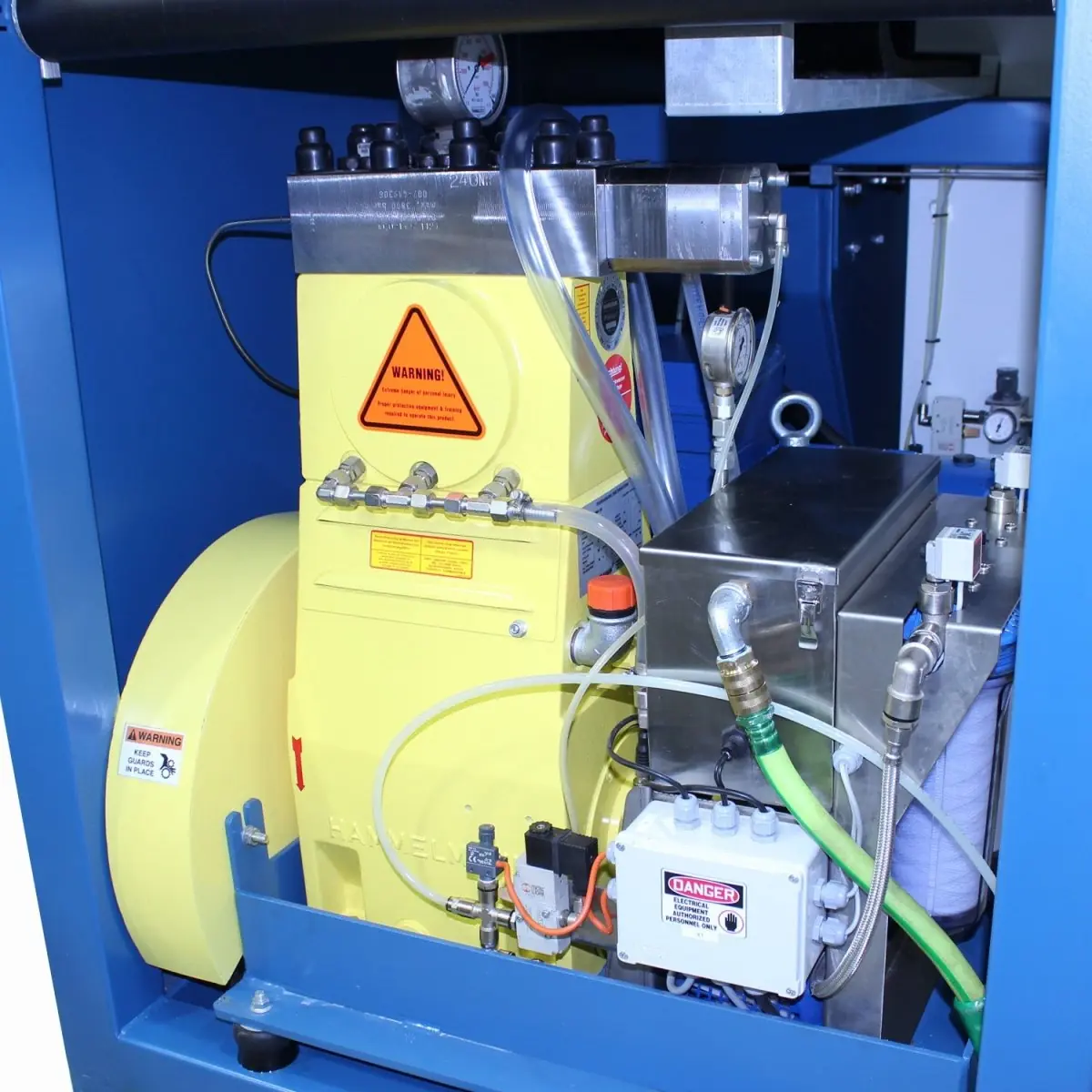

Because of the smooth action of the gantry, this water jet has the ability to cut just about any material with precision. This includes glass, granite, ceramic, plastic, foam, mild steel, stainless steel, titanium, aluminum, and copper in its 60” x 96” table. To help keep maintenance to a minimum, Every WJ-85CNC includes our own proprietary abrasive auto feed system that is coupled with a 55,000psi Hammelmann direct drive pump . This system is unique to the Baileigh Industrial line and offers a low maintenance approach to water jet cutting.

Controlling the WJ-85CNC water jet Baileigh Industrial could not be easier. The water jet saw includes an easy to use windows based stand alone operator console. This programmer will support DXF.

BOBCAD-CAM V29 EXPRESS DESIGN SOFTWARE (INCLUDED)

The WJ-85CNC comes standard with BobCAD-Cam Express programming software. You can design or plot out your project on any computer and load the plasma table via a USB drive. To learn more or download a free trial, click the BobCAD-Cam logo above.

For more information on the WJ-85CNC water jet from Baileigh Industrial contact a representative today.

| Item Number | WJ-85CNC |

|---|---|

| Motor KW | 30kw |

| Working Table Size | 96″ x 60″ |

| Working Table Travel (X/Y) | 96″/60″ |

| Table Size | 102″ x 63″ |

| Filter Type | 2 Stage/2 Filter, 10 Micron & 1 Micron |

| Number of Filters | 2 |

| Supported File Formats | DXF |

| Repeatability Accuracy | ± .001″ |

| Production Pressure | 56,000 psi |

| Max. Pump Pressure Outflow | 7.92 gallons per minute |

| Orifice Size | .014″ |

| Travel Speed | 40 fpm (26 fpm Cutting) Maximum |

| CNC System | Windows Based |

| Cutting Accuracy | ±.001″ |

| Inlet Pressure | 30 psi |

| Motor | 40 hp |

| X Axis Travel | 98″ |

| Y Axis Travel | 59″ |

| Z Axis Travel | 6.75″ |

| Power | 460V / 3-phase 60amp |

| Shipping Weight | 5600lbs |

| Hopper Capacity | 250 lbs |

| Software | BobCad Cam |

| Shipping Dimensions (Inches) | 153x46x80, 112x73x36, 69x44x25 |

* specifications subject to change without notice.