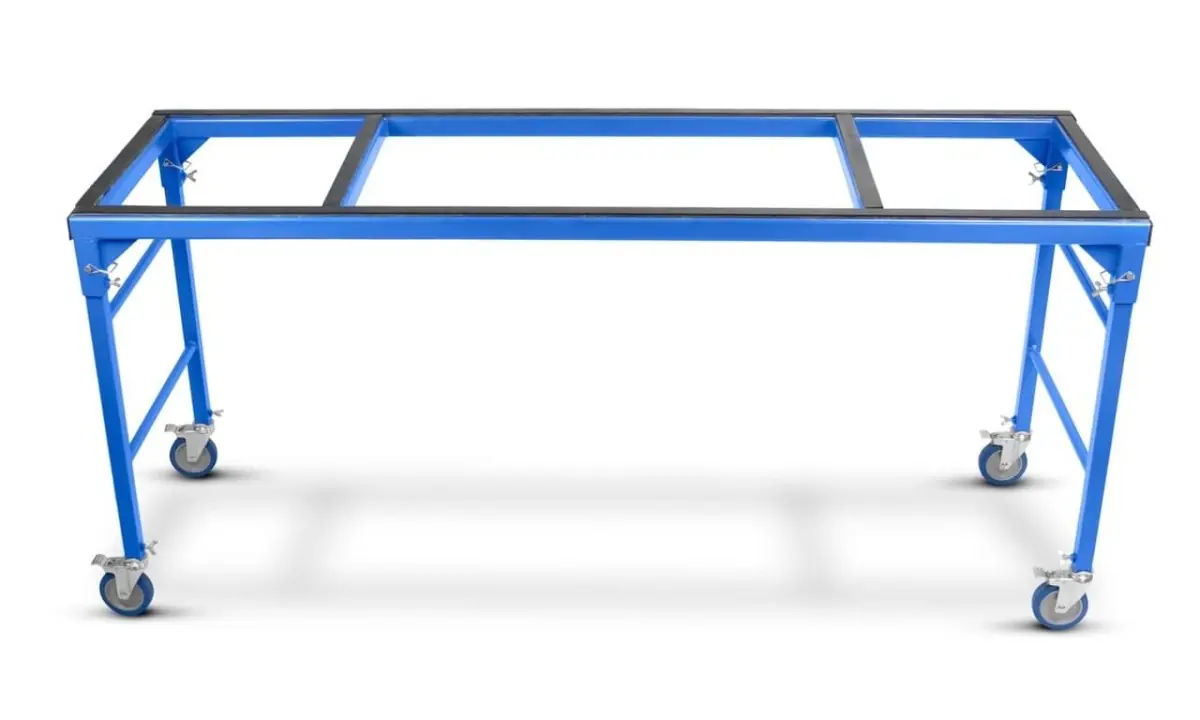

The BP-2-30-SUPER is designed for medium to large jobs including industrial plant and warehouse floors, parking garages, bridge decks and other horizontal applications.

The BP-2-30-SUPER has an impressive 30” cleaning path for class leading production on large jobs. The drive system features the new AC inverted drive motor with an integrated brake system that allows it to maintain speed on incline and declines for precise control. The BP-2-30-SUPER features a high speed travel switch which allows the machine to be quickly re-positioned without adjusting the speed potentiometer setting. The blast motor soft start device dramatically reduces mechanical start up trauma and reduces start up current, and the dual shot valve control handles allow the operator to independently control amperage on each blast wheel. The BP-2-30 Super incorporates the rear caster quick lift design for easy transport loading and offloading.

Advantages

- Ultra-high Production Output

- The equipment and all wear parts are manufactured in the U.S.A and there is typically no lead time when ordering parts

- The electrical box and electrical components are engineered and constructed by a UL508A Panel Facility

- Electrical enclosures are built to NEMA 4 specifications

- The positive sealing shot valve prevents shot from leaking even when using very small shot

- The interlocking liners protect the blast housing and reduce wear

- The sliding cleanout drawer is designed to quickly and easily remove debris from the shot hopper

- The improved separation system keeps shot cleaner and increase the life of wear parts

- The high speed bearing unit contains replaceable bearings which reduces operating costs and down time

- The type W 4/4 electrical cord is the toughest and most wear resistant cord available

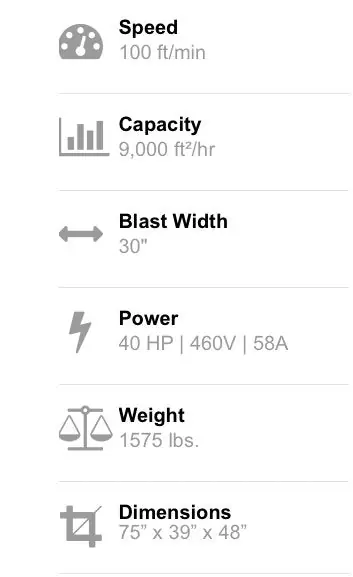

Speed

100 ft/min

Capacity

9,000 ft²/hr

Blast Width

30″

Power

40 HP | 460V | 58A

Weight

1575 lbs.

Dimensions

75” x 39” x 48”