Curve Cutting on Granite and Eng. Stone

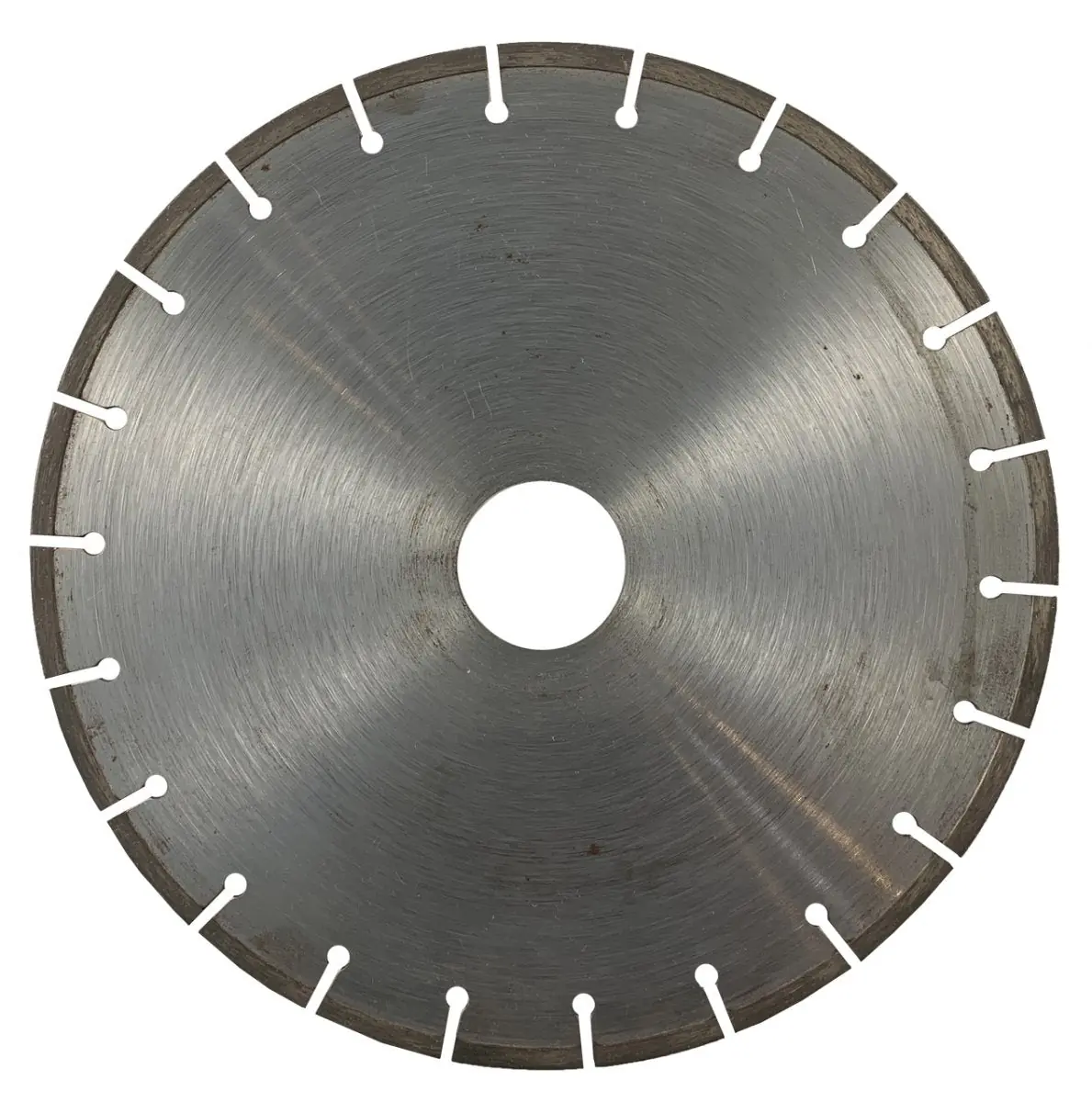

The Alpha® Contour Blade features blade design specifically developed for cutting granite sinkholes. The Alpha® Contour Blade also works very well on all curved cutting applications for engineered stone and harder types of marble. The special design incorporates direct sintered diamond segments on both sides of the steel core, as well as, on the peripheral cutting edge. This allows the blade to cut the curved area cleanly, accurately and safely while allowing a wider kerf, thus giving the blade easier cutting ability. The diamond segment on the inside of the steel core prevents undercutting, which is a common problem with curve cutting applications. Due to the excellent cutting ability and the wider kerf, there is a marked increase in maneuverability over that of a standard blade. This eliminates the need to perform difficult and time-consuming plunge cuts. The Alpha® Contour Blade can be used either wet or dry. It is versatile and fits on most common angle grinders. The Alpha® Contour Blade is unique and very cost-effective. The capabilities and long life of the Alpha® Contour Blade makes it the best choice for any curve cutting application.

- Design Specifically Developed for Cutting Granite Sinkholes

- Best Seller for Sinkhole Application

- Works Very Well On Engineered Stone and Harder Types of Marble

- Cuts Curved Areas Cleanly, Accurately and Safely While Allowing A Wider Kerf

- Direct Sintered Diamond Segments On Steel Core Prevents Undercutting

- Eliminates The Need To Perform Difficult and Time-Consuming Plunge Cuts

- Fits On CNC Router with Cutting Head

- Can Be Used Either Wet or Dry

| Part No. | Size | Thickness | Maximum RPM | Arbor(s) | Depth Of Cut |

|---|---|---|---|---|---|

| CCB004 | 4″ | 4.0mm | 14,500 | 20mm | 3/4″ |

| CCB045 | 4-1/2″ | 4.0mm | 13,200 | 7/8″ | 3/4″ |

| CCB005 | 5″ | 4.0mm | 12,200 | 7/8″ | 1-1/4″ |

| CCB006 | 6″ | 4.0mm | 10,100 | 7/8″ | 1-5/8″ |