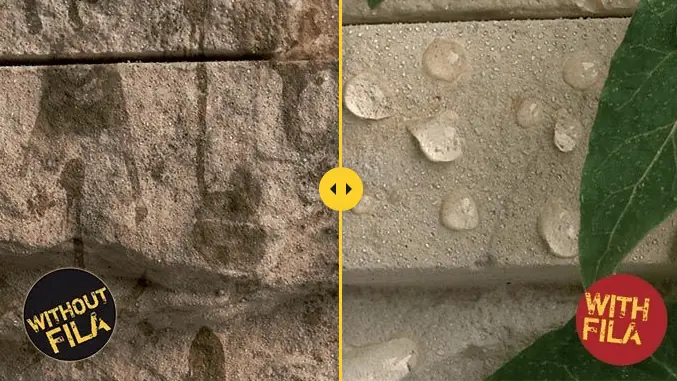

HIDRO PROTECTOR MM is a high-performance impregnating treatment to protect natural stone against staining and the harmful effects of water and rising damp.

It is characterized by a 100% water-based, eco-friendly formula and for its lack of volatile organic compounds (V.O.C. Free); therefore, its use is not harmful to the environment or for the health of users, either during or after application. The specific characteristic of HIDRO PROTECTOR MM is that it penetrates natural stone deep down, ensuring strong, lasting protection without compromising the original breath-ability of the surface, since it does not create any type of film. It also does not alter the original appearance of the material.

HIDRO PROTECTOR MM is a product that combines water repellent properties with a stain-proofing function in a single solution, especially on glossy surfaces. It also adds a marked resistance to rising damp, responsible for the majority of problems generally found on natural stone: persistent damp marks, formation of rust, yellow damp marks, flaking or detached surfaces (pitting), salt efflorescence and surface aggression. Unlike traditional stain-proofing protective treatments available, HIDRO PROTECTOR MM helps to increase the resistance of the natural material to dirt and foot traffic, working as a definitive solution due to its high resistance to the action of dewaxers.

HIDRO PROTECTOR MM is also certified for contact with foods and therefore, is a valid solution for protecting kitchen worktops.

HIDRO PROTECTOR MM is particularly recommended for pre-installation treatment on natural surfaces: – it is used as a 6-side pre-treatment to combat any form of rising damp and to ensure maximum protection. In this case, the installation of slabs or tiles must be carried out using high-quality adhesive or mechanical fastening and is used as a 5-side pre-treatment (top+edge) without any further processes. In this case, the installation of slabs or tiles must be carried out using a medium-high-quality adhesive. It can be used as a pre-treatment on 5 sides (top+edge), together with a treatment applied to the underside (bottom), in the event that slabs or tiles are used with a medium-low quality adhesive or simple cement-mortar mix. Pre-treatment of natural stone is highly recommended as it makes it possible to protect natural materials from the earliest stages of installation, avoiding all problems linked to moisture absorption from the laying bed (screed and adhesive) or the processes that the natural stone undergoes (bonding, grouting, mechanical polishing). It is always advisable to pre-treat natural stone, but it is more important to do so when the surface is absorbent and sensitive, especially and above all, according to the characteristics and performance of the adhesive used.

Excellent stain-proofing properties on polished materials, Protects material from rising damp, Prevents the formation of salts and efflorescence, Water-based product, Eco-compatible solution, VOCs Free, Suitable for contact with foods. Does not change the original appearance of the treated surface and does not film. High capacity to penetrate into the sub-floor. Durable protection. Simplifies grout removal and cleaning after installation. Does not change breath-ability.

Available in 5 Liter or 1 Liter Bottle.

COVERAGE: 10/15 m2 /l

APPLICATION EQUIPMENT: Brush, Lambswool applicator, Roller, Airless, Immersion, Production line

APPLICATION STEPS: Preparing and cleaning the surface

1. Carefully clean the surface, making sure to remove any dust or dirt present.

2. Never apply HIDRO PROTECTOR MM to wet surfaces. The product can be used on slightly damp surfaces; nonetheless, please ensure that the surface to be treated is as dry as possible.

3. Apply HIDRO PROTECTOR MM to surfaces with a temperature of between +5 and +40°. 4.

Any adjacent surfaces not being treated with the product must be protected.

Application as pre-installation treatment: This operation is generally carried out in the factory or on site, including a short period from material installation. Usually, material for laying is treated during the “dry laying” stage, which is frequently used as it allows the position of each single piece to be assessed. Alternatively, we recommend laying out the material on a clean, dry area that is large enough to treat the natural stone slabs or tiles. The natural stone pre-treatment stage using Faber Chimica solutions starts from the upper surface of the material (top) and then the sides (edges), followed, after the product has dried, with the under-face, which will be in contact with the glue (bottom). 5-a. Apply a layer of product, taking care to create an even coating that covers the whole surface, including both the top and edges of the slab or tile. After about 5-10 minutes and in any case, before the product dries, even out any product residues remaining on the surface, taking care to distribute them uniformly with a roller, lambswool applicator or brush. For a perfectly clean surface in this stage, we recommend redistributing residues until they have been completely eliminated. This redistribution operation is essentially important since it allows easy removal of any dry residues on the surface of the material, which if not re-distributed will be particularly hard to remove. 6-a. Wait around 1-2 hours for the product to dry; reposition the slabs or tiles in order to be able to treat the underside (bottom), proceeding as described above. We recommend re-positioning the slabs and treating the underface (bottom), starting with the first slab to have been given top + edge treatment. This process applies when using HIDRO PROTECTOR MM and also when using a different product for the underside only. 7-a. The product residues, redistributed as described above, can be easily removed once the material is completely dry and before it is boxed up, using a white pad or a damp cloth. It can also be removed directly on site, before the slabs or tiles are laid, using a white pad or damp cloth, or immediately after laying, using a floor polisher with white disc. If the material laid needs to be polished, the residues will be removed directly during the polishing operations. Protective HIDRO PROTECTOR MM-High-performance, eco-friendly, water-based, impregnating sealer to protect natural stone against rising damp and stains. The pre-treatment on 6 sides (top+edge+bottom) with HIDRO PROTECTOR MM can be carried out using roller, brush or lambswool applicator, or by completely immersing the individual tiles. In this case, fill a large enough container for the tiles with product and completely immerse one tile at a time, for about 10-15 seconds. Immediately after, proceed to redistribute the product residues over the surface, as described above, using a clean cloth. Drying time for pre-installation treatment. Before proceeding to lay the tiles or slabs treated with HIDRO PROTECTOR MM wait at least 24 hours. Opening to floor traffic after pre-installation treatment Once laid, the treated slabs or tiles can be opened to foot traffic. Application as post-installation treatment: 5-b. Apply a layer of product, taking care to create an even coating that covers the whole surface. After about 5-10 minutes and in any case, before the product dries, even out any product residues remaining on the surface, taking care to distribute them uniformly with a roller, lambswool applicator or brush. This redistribution operation is essentially important since it allows easy removal of any dry residues on the surface of the material, which if not redistributed will be particularly hard to remove. 6-b. The product residues, redistributed as described above, can be easily removed using a white pad or a damp cloth in cases of surfaces with a limited area or using a floor polisher with white disc for larger areas. When applying to a porous and therefore, more absorbent surface, where HIDRO PROTECTOR MM is absorbed without leaving residues, we recommend a second coat of product. It is also possible to increase the dirt-resistant properties added by the product, by polishing the surface with a floor polisher and white disc. If the material laid needs to be polished, the residues will be removed directly during the polishing operations. Opening to floor traffic after post-installation treatment:The surface can be opened to floor traffic about 2-3 hours after the product has been applied. Drying time for post-installation treatment: The product will be completely dry in about 24 hours, during which it must be protected against all contact with water or moisture.

Production line application: The product can be applied using special equipment as part of an industrial production/treatment line. Based on the characteristics of the line available, the product will generally require an application stage using a sprinkler, silicone roller or other suitable means; this must be followed by the removal of residues, to be carried out with special brushes or pads.