Planer/ Grinder for flooring with Laser system to assist the grinding of CONCRETE flooring in order to reach requirements of flatness needed for the safe operation of VNA forklifts.

FAST, ACCURATE, RELIABLE, PROFITABLE

HG Hyper Grinder redefines the method of planing industrial floors with a laser system.

The modern logistic warehouses with high capacity and narrow lanes (VNA), need a paving with almost perfect flatness; In fact, the trilateral trolleys would not be able to move easily in height if continually shaken by the unevenness of the floor.

A traditional industrial floor is not suitable for this type of warehouse. The unevenness of the floor can frequently cause serious safety problems, decelerations in the handling of goods, and, in some cases, a total block.

The alignment for “narrow corridors”, is up to only 1650mm wide and up to 16 meters of height, allowing a very high density of storage of goods, as well as an optimal speed for flow of storage.

High efficiency is possible thanks to the almost “surgical” precision of the forklifts created for this specific use.

However, it should be remembered that the flooring is the work plan on which all logistic activities are carried out, therefore VNA trolleys must operate on a flooring with the correct characteristics required. There isn’t enough importance given to the characteristic requirements of flooring, and to the tolerance for baring the weight of the shelves. Apart from discovering once the site is completed that the beautiful Trolleys cannot move on a traditional type of flooring.

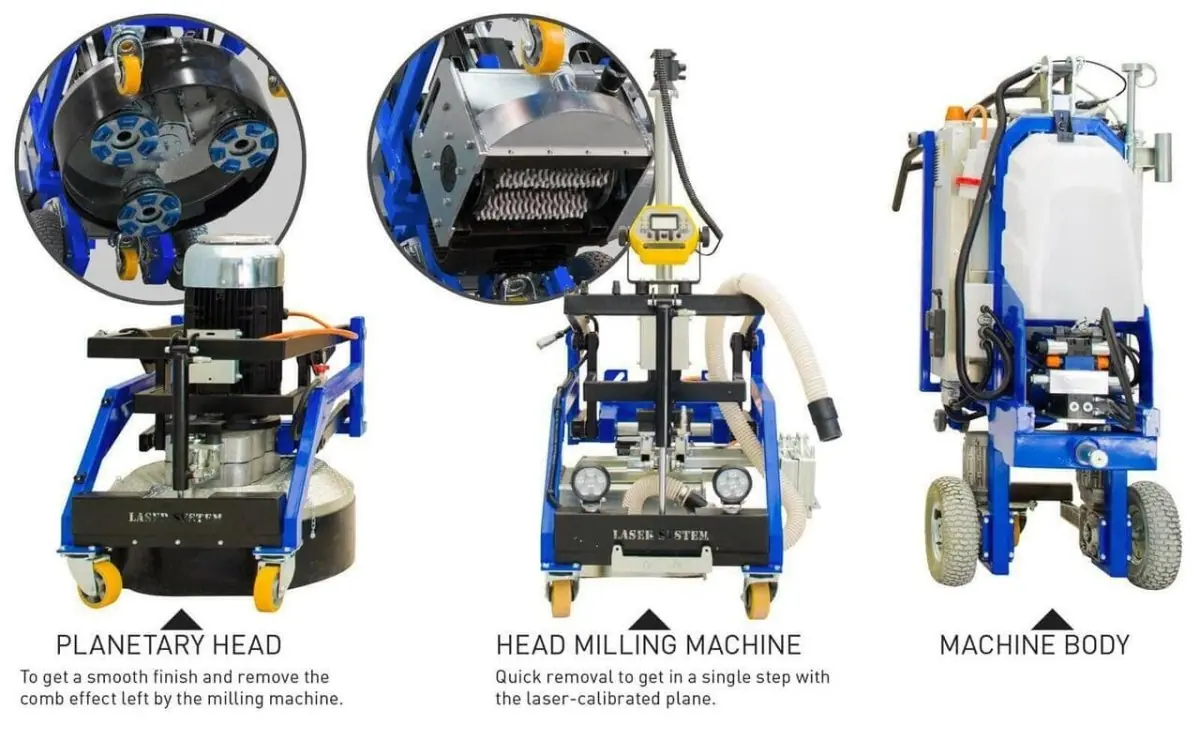

HG HYPER GRINDER introduces the new HYPER FLAT FLOOR planer/Grinder with automatic leveling with a Laser system that allows to obtain the perfect evenness for the lanes suitable to operate VNA trolleys.

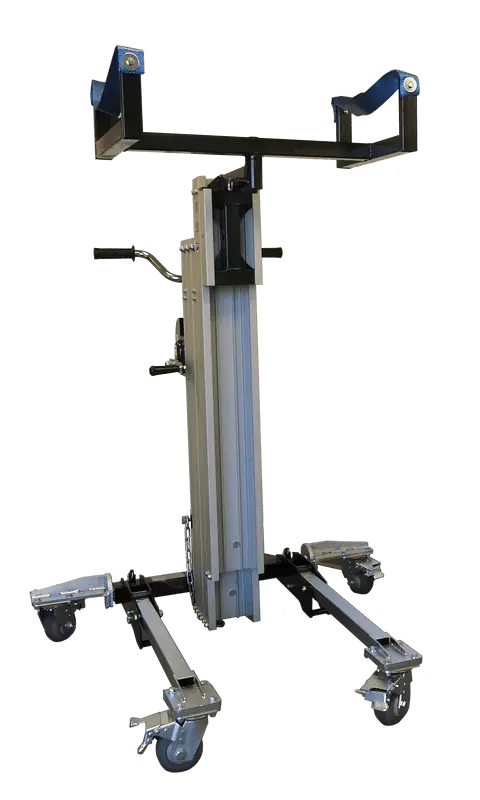

The HYPER FLAT FLOOR GRINDER has been specifically designed to work in an operating warehouse, in order to not cause even the slightest inconvenience for the clients workers.

HYPER FLAT FLOOR GRINDER is able to do the planing of the floor both dry and with water and does not release dust in the environment and can work even in the presence of shelves with full loads of goods and in the food and pharmaceutical or electronic sectors.

2- Milling head with roller or Multi-blade machine. Maximum flexibility of use:

- Concrete Society TR34 (English area)

- Din 15 185 (German area)

- Din 18 202

- Fmin (US area)

INCREASES THE EFFICIENCY OF THE WAREHOUSE.

With the exclusive HYPER FLAT FLOOR system you will get the highest possible flatness in the floor of your warehouse according to the highest standards and standards in force.

Having adequate flatness means obtaining the following advantages:

-

Higher speed of the trolleys.

-

Increased work safety.

-

Higher efficiency.

-

Reduction of maintenance costs.

-

Better quality of work.

The planning procedure uses sympathetic inclinations to improve the flatness of the floor, working according to the requirements of the specific request. It removes the minimum thickness possible to create the maximum benefit for the customer.

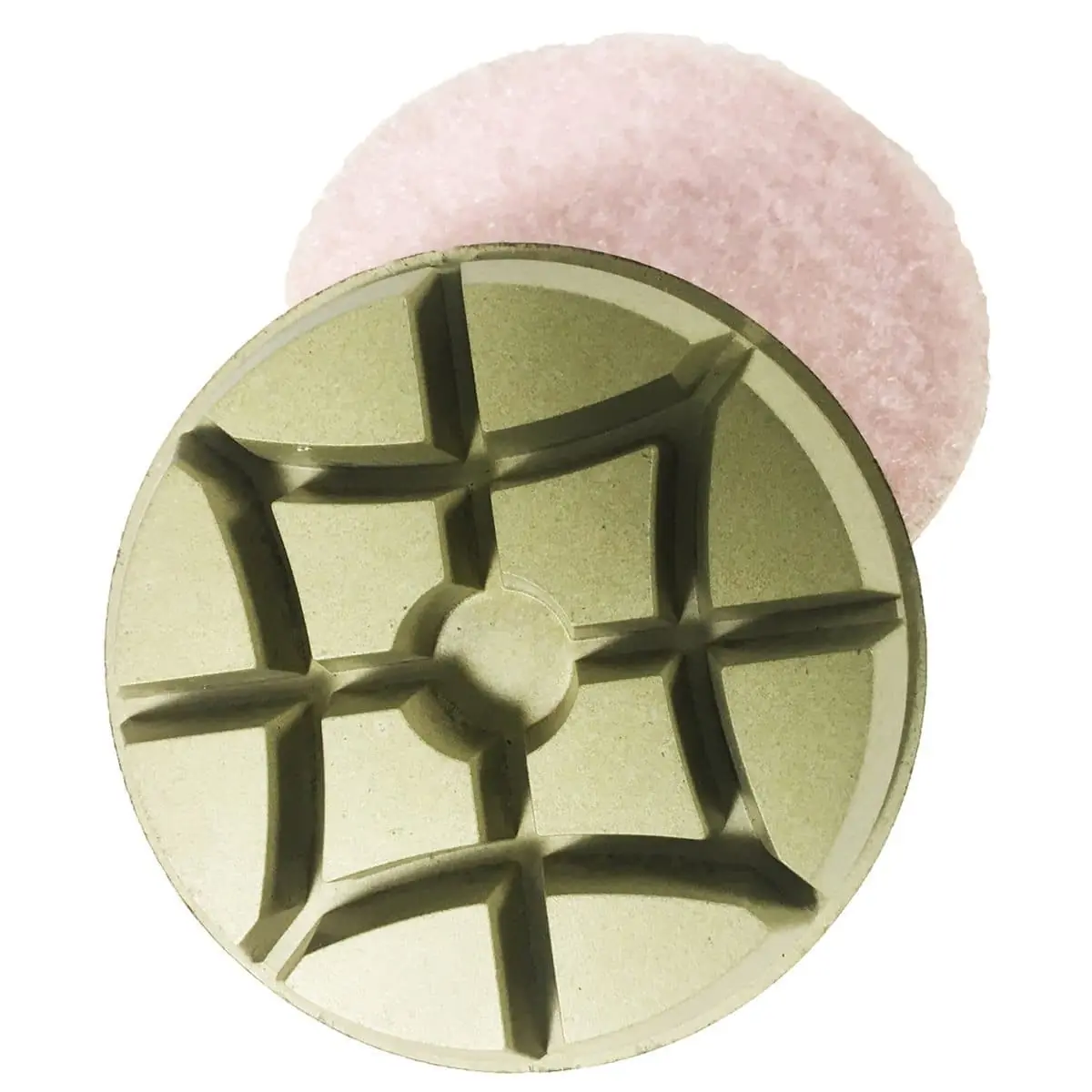

FLOOR PLANARITY PADS

- Concrete Society TR34 (UK area)

- Din 15 185 (German area)

- Din 18 202

- Fmin (US area)