RQP is a multi-purpose 100% solids, 1:1 industrial epoxy repair compound engineered for fast track repairs or to be used as an adhesive for flooring accessory installations.

- 32oz Kits

- 2 gallon kits

- 300x300ml dual cartridge kits with 1 static mixer tip

- VOC compliant

- Non-shrink

- Good working time, but fast cure time

- Easy 1:1 mix ratio

- Easy application

- High bond strength and tensile strength

Description

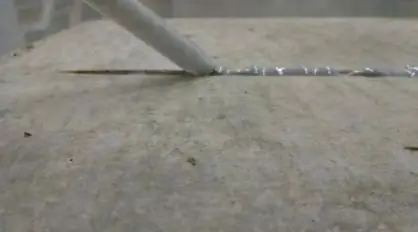

RQP is manufactured in two versions. Standard RQP is a highly thixotropic compound that is used to patch horizontal, vertical or overhead substrates. ROCK-TRED’s quick set epoxy can be hand mixed and easily applied using a putty knife, hand trowel or plastic applicator out of our conveniently packaged units. Gun Grade RQP is less thixotropic and is used to patch horizontal substrates or to apply beads of RQP to adhere accessories such as terrazzo strips, termination cap, etc. Gun Grade RQP is packaged in 300ml x 300ml dual cartridge tube sets. These are applied using a dual cartridge caulk gun (available separately from ROCK-TRED) and a static mixing tip included with the Gun Grade RQP purchase.

Uses

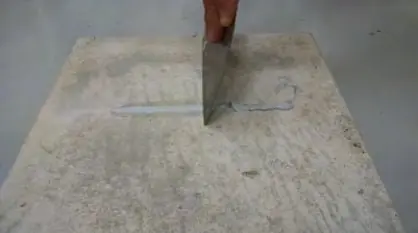

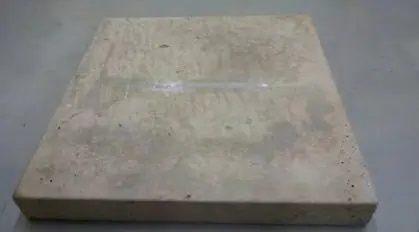

RQP’s easy workability and rapid cure time make it an ideal product for last minute “touch ups” to missed pop-outs or small cracks in a substrate prior to applying a coating system. RQP is used to repair chips, defects, small voids or “honeycombing” in horizontal, vertical and overhead concrete substrates. RQP’s excellent bond strength, thick consistency and quick setting attributes make it an ideal adhesive to use when setting preformed “speed cove”, terrazzo strips or termination caps. RQP can be sanded immediately after cure and is strong enough to be drilled, tapped or shaped as needed to conform to the substrate being repaired.

Typical Coverage

RQP quick set industrial epoxy can be applied to a “feather edge” as thinly as a blade can strike it off and to nearly infinite depth. Ideally, RQP is applied in lifts less than 3/8″ and not over areas more than 2 times wider than the repair depth. Deeper fill repairs may require two or more lifts allowing for cure in between applications.

Physical Properties

| Volume mix ratio | 1 to 1 Part A to Part B |

| Viscosity (mixed) | 125,000 CPS (Standard RQP) 4,000-5,000 CPS (Gun Grade RQP) |

| Solids Content (%) | 100% solids |

| VOC | Compliant with all US Regulations |

| Application Temps. | 50° – 80° F. |

| Hardness (ASTM D-2240) | 85 (Shore D) |

| Gel Time | 15 minutes |

| Dry to Touch (recoat with compatible product) | 30 minutes |

| Through Cure (able to sand) | 45 minutes |

Limitations & For Best Results

- Do not thin this product.

- Do not apply when humidity exceeds 70% indoors./li>

- Allow each coat to dry to ‘tack-free’ prior to recoat.

- When re-coating, always apply the next coat within 24 hours of completing the previous coat.

- Relatively thin applications (¼” width or depth) of RQP are best – avoid deep fill repairs in a single lift as minor cracking during cure may result.

- Mix thoroughly until a uniform gray color is achieved.

- Tube Set applicator works best when material is above 65°F.

Product Application

Apply by putty knife, trowel, plastic applicator or directly from the dual cartridge set through the static mixer. ROCK-TRED product test data is based on environmental temperatures of 75° F (24° C). Viscosity and working time are always affected by temperatures above or below that mark. When applying product – always consider the ambient, surface, and product temperature at the time and place of installation.

Colors

RQP is only available in gray. The resin component is BLACK and the hardener is WHITE so when mixed properly a uniform gray color is achieved.

Chemical Resistance

Always refer to ROCK-TRED’s chemical resistance chart for specific information on each product / system or contact ROCK-TRED directly.

Product Storage

DO NOT allow ROCK-TRED products to freeze. All ROCK-TRED products should be properly stored above the floor on pallets or shelves, and in an area that has a constant minimum temperature of 50°F.

Surface Preparation

Always apply ROCK-TRED products to a clean / sound substrate that is free of laitance, grease, oils, debris, and curing compounds. Concrete substrates should be cured for a minimum of 28 days prior to application of product [except as otherwise noted on the individual Product Data Sheet]. Whenever possible, remove existing coatings and/or flooring systems completely; if complete removal is not possible always perform tests to determine adhesion and compatibility to the existing flooring. Mechanical surface preparation to a CSP-2 minimum profile by means of a diamond grinding machine is the best and recommended preparation method for RQP. If the substrate is not properly prepared and the appropriate profile is not achieved, failure of the product to adhere to the substrate may occur.

Clean Up

Application tools and equipment can be cleaned with soap and water immediately after use, or with solvent once the product has begun to cure.

Disposal

Product containers will contain product residue and must be disposed of properly. Label warnings must be observed at all times. All containers must be disposed in accordance with federal, state, and local regulations.

Important Notice

Always read and acquaint yourself with ROCK-TRED’S Product Data Sheet, SDS [safety data sheet], and product labels for each individual product prior to mixing and prior to use. For further assistance, product questions, additional information and/or unexpected or unusual installation conditions – contact your local representative or ROCK-TRED directly for recommendations. Kit components are pre-measured for optimal performance. Catalyzation errors due to incorrect mixing in the field voids product warranty.