Premium, Polymer Modified, Dustless Portland Cement Sanded Grout

SikaTile®-800 Sanded Grout is a premium-grade, pre-blended, polymer-modified Portland cement tile grout that requires only the addition of water for mixing. For grout joints from 1/8″ to 1/2″ (3 mm to 13 mm), SikaTile®-800 Sanded Grout provides color consistent, hard and durable grout joints and features innovative Dustless Technology producing approximately 80% less dust than ordinary cement grouts and is designed to promote cleaner working conditions and reduce mess.

- Polymer modified for hard, durable, professional results

- Stain resistant and color consistent

- For 1/8″ (3 mm) to 1/2″ (13 mm) grout joints

Usage

- For interior and exterior applications in both residential and commercial applications in dry or wet conditions.

- For floors, walls, countertops and submerged conditions.

- For joint widths from 1/8″ to 1/2″ (3 to 13 mm).

- For application in submerged conditions (swimming pools, spas, water features and fountains), after 21 days.

SUITABLE TILE TYPES

- Brick and thin brick

- Cement-based precast terrazzo

- Impervious porcelain and glass tile

- Natural stone tile, granite and slate

- Vitreous, semi-vitreous or non-vitreous tile

- Ceramic, mosaic, quarry, cement body tile

Advantages

- Polymer modified for hard, durable, professional results

- Stain resistant and color consistent

- For 1/8″ (3 mm) to 1/2″ (13 mm) grout joints

- Easy mixing – just add water, no additives required

- For interior and exterior floors, walls and countertops

- Dustless formula – provides approximately 80% less dust than ordinary grouts

- Promotes cleaner working conditions by minimizing dust

- Creamier and easier to spread

- Uses less water for consistent hydration and quicker drying

- Longer working time

- No-Slake – No wait. Just mix, trowel, and install

- Mold and mildew resistant

Packaging

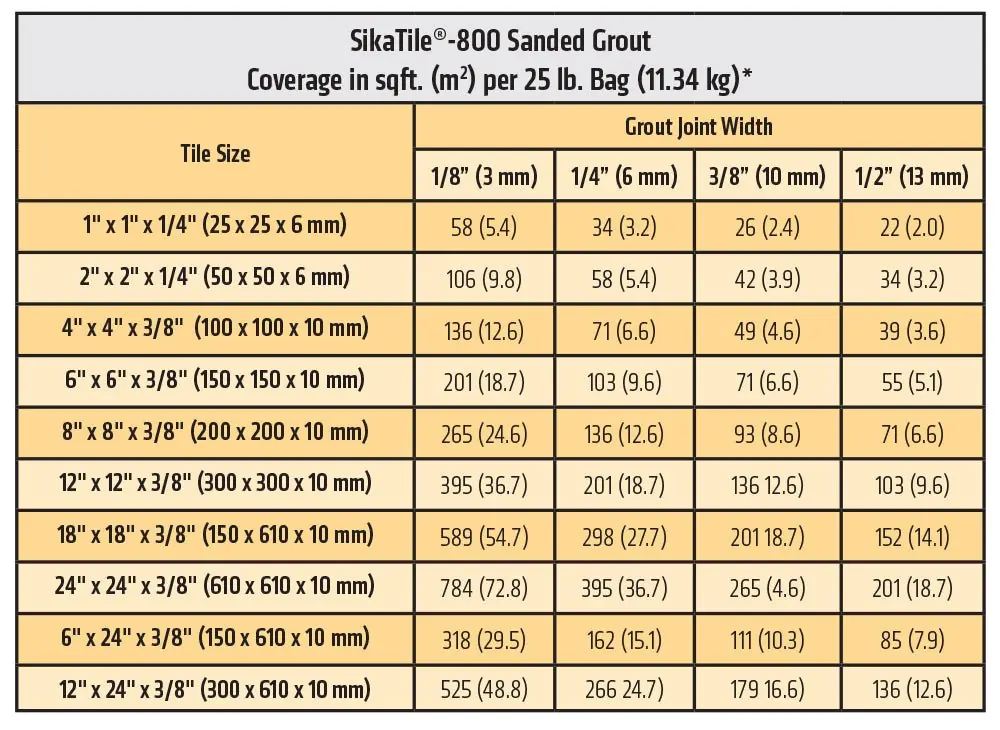

25 lb. (11.34 kg.) bag

Color

Available in 18 colors; Refer to SikaTile® grout kit or color card for actual colors

ENVIRONMENTAL INFORMATION

Sika® is committed to environmental responsibility in both products produced and in manufacturing practices. Use of this product can contribute towards LEED® v4.1 certification:

- Up to 2 points towards MR Credit 5, Regional Materials

- Up to 1 point towards IEQ Credit 4.1, Low-Emitting Materials – Adhesives & Sealants

APPROVALS / STANDARDS

American National Standards Institute (ANSI) — ANSI A108.10 and A118.6 of the American National Standards for the Installation of Ceramic Tile ASTM International (ASTM)

- ASTM C109 Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2” or 50mm Cube Specimens)

- Resilient Floor Covering Institute – (RFCI) Recommended Work Practices for Removal of Resilient Floor Coverings

- Tile Council of North America (TCNA) – TCNA Handbook for Ceramic Tile Installation, TCNA EJ171 Movement Joint Guidelines.

Chemical Base

Portland cement, selected aggregates, water retention additives, re-dispersible polymer

Shelf Life

12 months from date of production when stored in original, sealed package

Storage Conditions

Store in undamaged, original, sealed package, in dry conditions at 73⁰ F (23⁰ C)

Compressive Strength

> 4,000 psi (ANSI A118.6 Section 4.5)

Flexural Strength

> 400 psi (ANSI A118.6 Section 4.7)

Tensile Adhesion Strength

> 300 psi (ANSI A118.6 Section 4.6)

Shrinkage

< 0.2% (ANSI A118.6 Section 4.3)

Water Absorption

< 10% (ANSI A118.6 Section 4.4)

Mixing Ratio

2 quarts (1.93 L) of cool potable water per 25 lb. bag

Pot Life

1 Hour

Applied Product Ready for Use

Do not disturb grout or walk over installed tiles for at least 24 hours after setting. Do not allow heavy traffic over installed tiles for at least 72 hours after setting. For residential showers and tub surrounds, restrict use for 24 to 48 hours after grouting. For steam showers, restrict use for 14 days after grouting. Like other Portland cement products, SikaTile®-800 Sanded Grout will reach full curing in 28 days

MIXING

To minimize color variation when using multiple containers of the same grout, dry blend the powders prior to the addition of water. Add approximately 2 quarts (1.93 L) of cool potable water for every 25 lbs. (11.34 kg.) of SikaTile®-800 Sanded Grout in a clean mixing container. Add the grout to the water slowly; blend by hand or power mixer at low speed (less than 200 RPM). The ideal grout looks stiff but has a creamy consistency. Periodic mixing during use keeps the grout workable, but do not add additional water or additives. When the grout becomes dry and difficult to work, discard and make a new batch. For best results on multiple mixes, have the same person mix the grout to ensure the repetition of the mixing technique.

APPLICATION

Read all installation instructions before installation and reference ANSI A108.10-1999. Slightly moisten the tile surface with a damp grout sponge before application. Holding a rubber grout float at a 45° angle, force grout diagonally into joints ensuring joints are completely filled. Remove excess grout using the edge of the float held at a 90° angle. Cleanup can begin as soon as the grout becomes firm enough to only be slightly indented when pushed. Use as little water as possible for grout cleanup. Excess water will cause variation in color and may cause shrinkage, cracks or pinholes. Smooth and level joints and, in a circular motion, remove excess grout from tile with a moist small-pore grout sponge. It is best to change cleaning water and rinse sponge frequently. Using clean water and sponge will enhance color uniformity. Remove haze from tile surface with a soft, dry, microfiber cloth.

FINAL CLEAN UP:

After 24 hours, the grout installation can be cleaned with clean water. Cleaning with acid is not recommended.

MOVEMENT JOINTS:

All expansion, control, construction, cold, saw-cut, isolation, contraction, and seismic joints in the structure should continue through the tilework, including such joints at vertical surfaces, as specified per TCNA Method EJ171 or TTMAC Specification Guide 09 30 00, Detail 301MJ.

MAINTENANCE:

Sealing is not required, but if used apply using a high-performance penetrating grout sealer following manufacturer’s directions. Grout must be fully cured for 21 days before regular cleaning. To maintain a clean tile surface, use a neutral-pH cleaner for maintaining the floor, followed by a clean-water rinse. Do not use harsh chemical cleaners to maintain the tile surface. Before proceeding with cleaning, consult the cleaner’s manufacturer for compatibility, use and application instructions. Remove or rinse fatty acid residue from the grout surface to avoid potential grout deterioration caused by prolonged exposure.

CLEANING OF TOOLS

Clean tools and tile with water before the material dries.