The TBG134 Bridge Deck Groover delivers more productivity, reduced grooving costs and less downtime.

Call for details 800-342-3876

Diesel Powered

Diesel Powered

Redesigned hydraulics for maximum efficiency and ease of maintenance.

FEATURES:

• Removable seat and flip up operators platform

• Night operation light package

• Safety strobe lights

• Adjustable carriage travel limit switches

• Lift eyes

• 90 gallon fuel capacity allows for up to 10 hours of operation

• Power steering

• Rear crab steer allows for operation in small areas

• Grooves within 12” (34.48cm) of curb or barrier wall

Specifications:

Engine: Caterpillar C4.4 174HP (129.7Kw) @ 2200rpm turbocharged/intercooled electronically controlled diesel engine. Meets U.S. EPA Tier 4 Final and EU stage IV emission requirements. Fuel consumption is approximately 9gph (34 LPH)

Fuel Capacity: 90 gallon (370L) diesel fuel

Tank Capacity: 70 gallon (259L) hydraulic oil

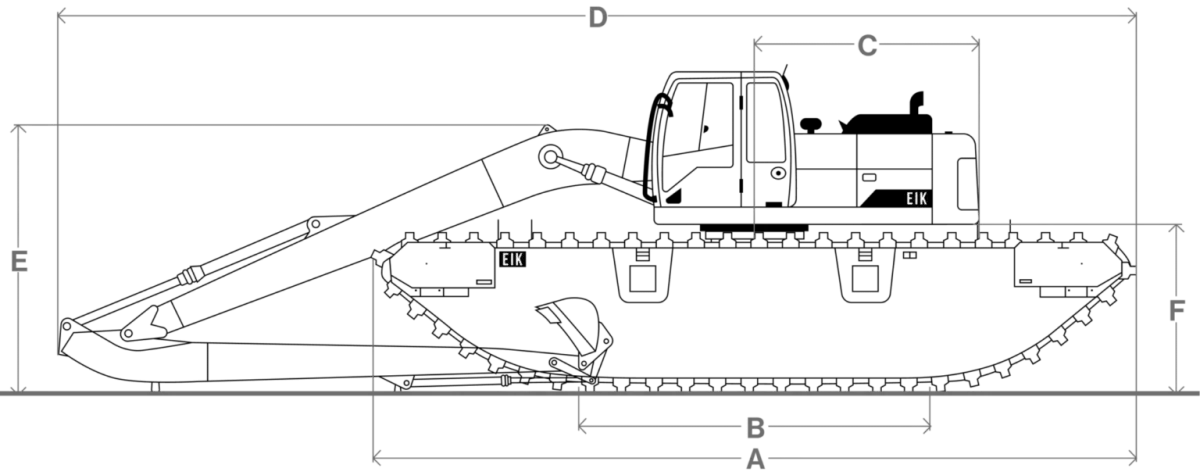

Dimensions: Length 8ft (2.44 meters), Width 8ft, 2in (2.47 meters), Height 10ft (3.04 meters), Weight 12,500lbs (26,400kg)

Cutting Width: 39in (99.06cm)

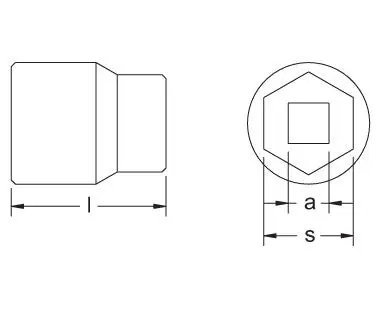

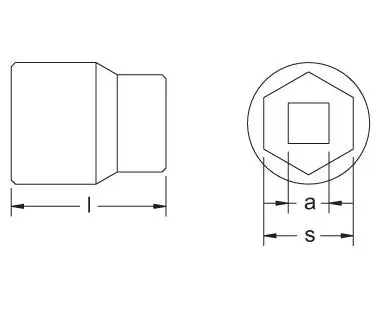

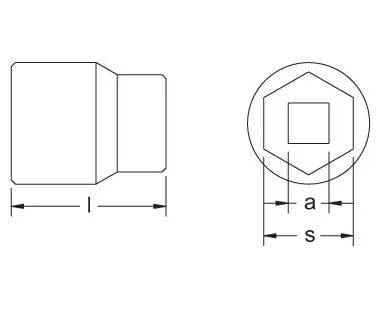

Blade Diameter: 12in (30.48cm)

Part #: TBG134, Catalog #: 90172

UNIQUE “CRAB” FEATURE

A switch is provided on the control panel which causes the rear drive wheels to pivot to 28 degrees. A quick turn of the steering wheel to full left lock positions the front wheels at the same 28 degrees. This allows the TBG134 to “crab” sideways while backing up and remain parallel to the previously cut grooves. The TBG134 can thus groove in a 12’ wide lane and realign for the next pass in one backward movement.

NO MACHINE ON THE MARKET TODAY OFFERS THIS FEATURE.

A bridge deck groover is a tool or machine used in the construction of concrete bridge decks. It is used to create grooves or joints in the surface of the deck to control cracking and improve the durability of the structure.

The grooves are typically created using a saw blade or a milling machine with a specialized cutting head. The grooves are typically spaced at regular intervals and extend partially or fully through the thickness of the deck. This allows the concrete to expand and contract with changes in temperature and humidity without cracking.

Bridge deck grooving is an important step in the construction process, as it helps to ensure the long-term durability and safety of the bridge. The grooves can also provide better traction for vehicles, improving safety for drivers and passengers.