TENAX FABRICATION BLADES

You know fabricators that work various materials need to have blades designed to cut a variety surfaces. Additionally, the blades need to be able to perform in just the right way for it to make sense. Tenax has developed a new group of products designed to help fabricators get the right blades for all sorts of materials; including quartz. If you are looking for non-quartz blades, you might be interested in our blades for porcelain materials or our blades for DEKTON.

QUARTZ FABRICATION BLADES

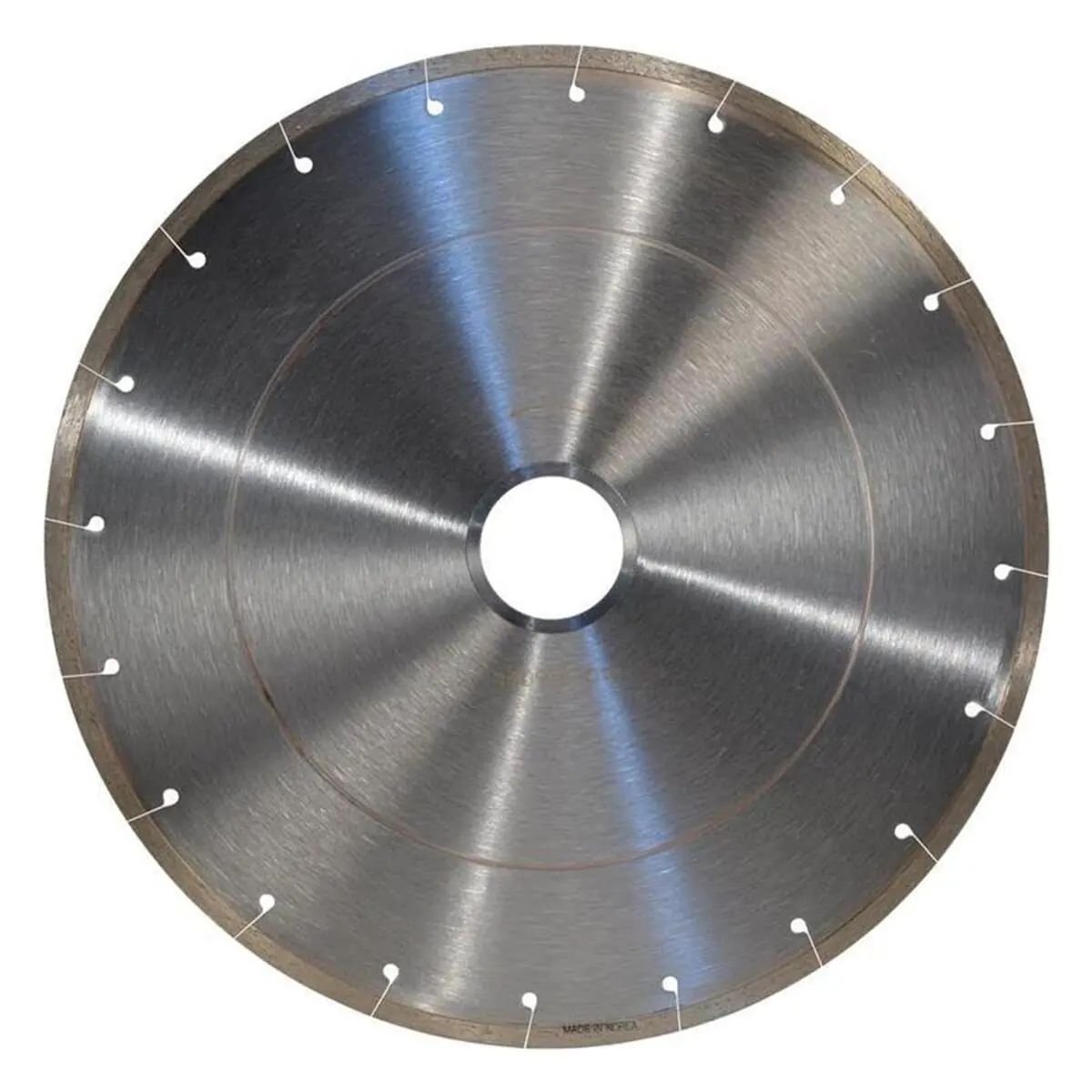

As you are aware, quartz is a very hard material and it requires a blade that is designed to work effectively on hard materials. It also needs to cut cleanly. Who wants a blade that cuts fast but not clean? By the same token, cutting clean but slow can cost you time; lowering productivity. After all, time is money. Tenax quartz blades are designed to give you a blade that performs well on quartz surfaces.

Quartz comes in a variety of grades like many other things. That’s why the Tenax quartz blades have been engineered to perform on all kinds of quartz material. Our cycle of product development includes a series of iterative steps to construct products that are well-suited for their intended purpose. These Tenax quartz blades are no exception to our research, design, and production process.

QUARTZ BLADE SPECIFICS

Our quartz blades are available in the following diameters:

- 14″ Quartz Blades

- 16″ Quartz Blades

- 18″ Quartz Blades

Designed to cut fast and last a long time, Tenax quartz fabrication blades feature a silent core and are made for wet use at a range of 1250-1500 rpms. Try these quartz diamond blades and see the results of our methodical research and development process.

- Diameters: 14″, 16″ and 18″

- Wet Use

- RPM: 1250-1500