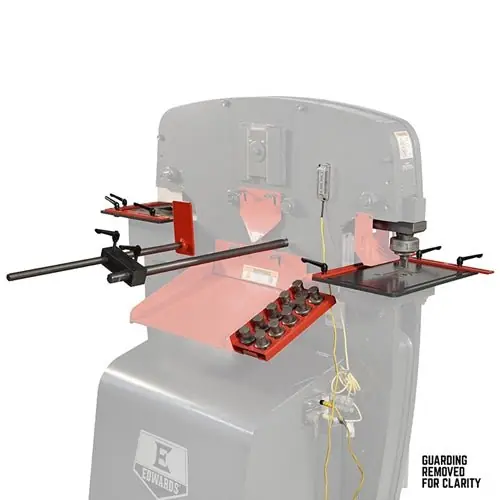

Designed to improve overall Ironworker Performance

FLEXIBILITY

- Contains Punches and Dies to produce the following size round holes: 3/16″. 5/16″, 7/16″, 1/2″, 9/16″, 5/8″, 11/16″, 13/16″, 15/16″, and 1-1/16″

- The Back Gauge utilizes a positive stop attachment that is fitted to the back of the Ironworker ensuing accurate shearing out to 48″

PRODUCTIVITY

- Punch and Die Storage Tray easily mounts to either side of the output shoot

- The 48″ Back Gauge speeds up production on repeatable cuts by providing an adjustable stop for the flat bar shear and angle shear.

- The Fabricator’s protractor increase accuracy on the punch and flat bar shear workstations by guiding your work piece and is gauged at 15° increments through 180° featuring a straight edge and reversible design

- Coper Notcher Gauging Table Kit includes adjustable fences and handles quickly and easily guides your material for perfect repeatable actions

- A Gauging table kit includes adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

SAFETY

- Punch diameter must meet or exceed the thickness of your material

- Super bright LED light with M12 connections has a powerful magnetic base allowing users to attach the light to any Ironworker surface and move as needed.

PERFORMANCE

- Made of durable steel for long life

- Long lasting averages between 3,000 and 5,000 impacts

- The Quick change punch assembly accepts both standard and oversize punch and die sets

- The 3/8” thick, 12” x 16” gauging table that adds precision to your punch workstation