Vespa Polishing Pads for grinding and polishing concrete

Coverage

Coverage can vary from surface to surface depending on roughness, porosity and density of the medium being

applied. Application technique can also vary the coverage. On flat, dense surfaces, the coverage should

generally range from 5000 to 8,000 square feet per pad.

- Diameters: 14″, 16″, 18″, 20″, 27″

- Thickness: 1 inch

- Maximum Speed: 1500 RPM

- Use WET or DRY

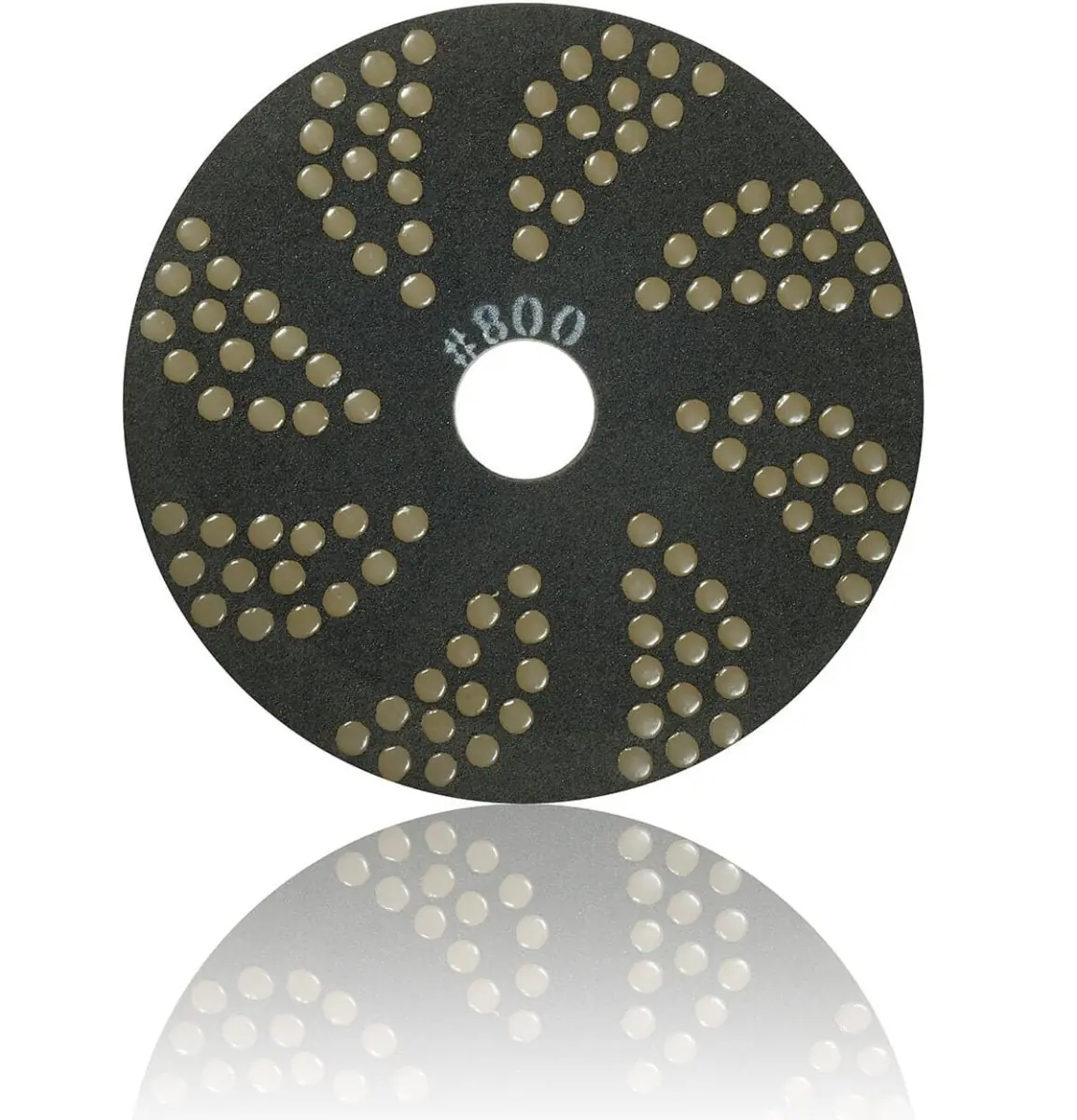

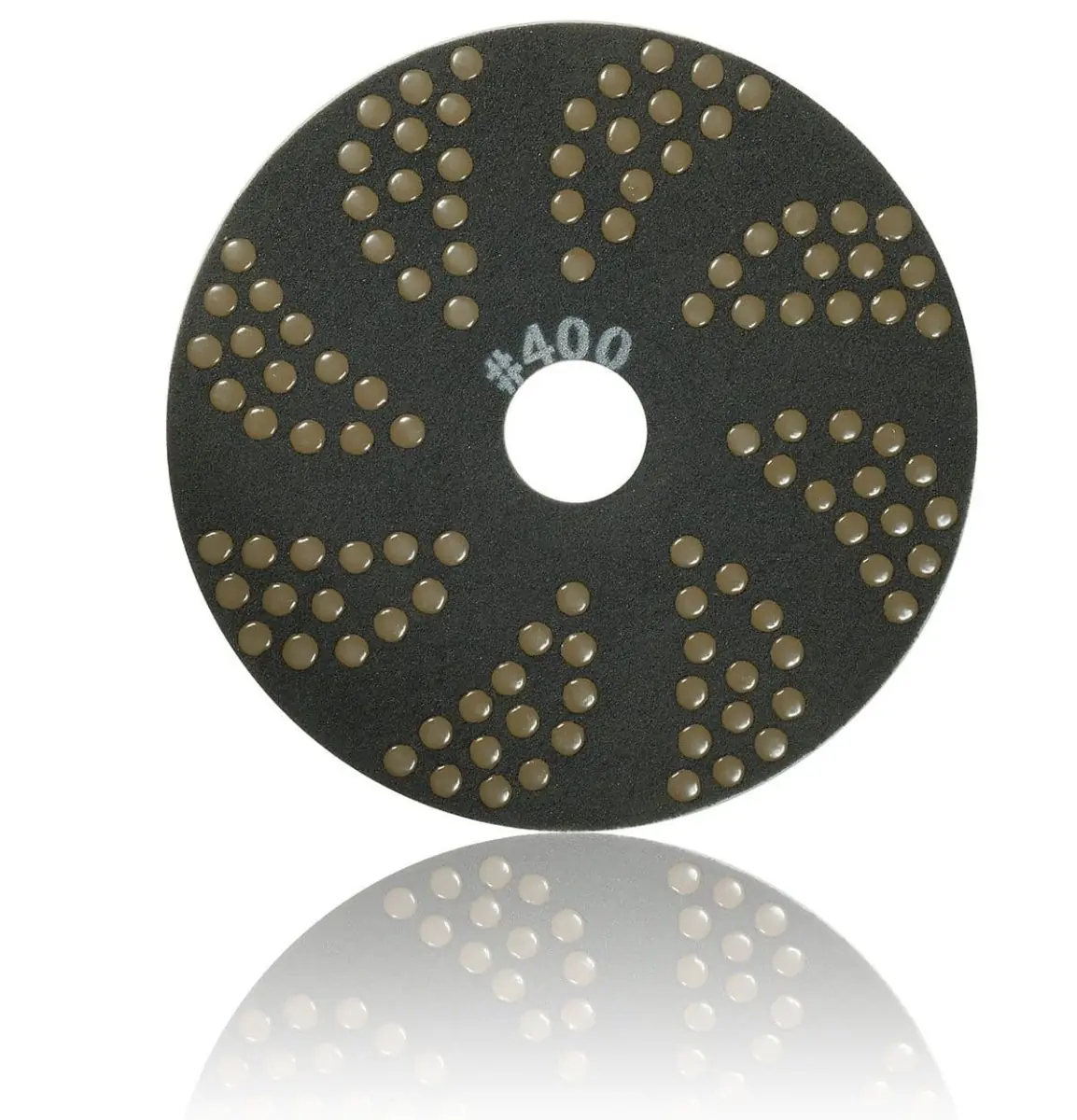

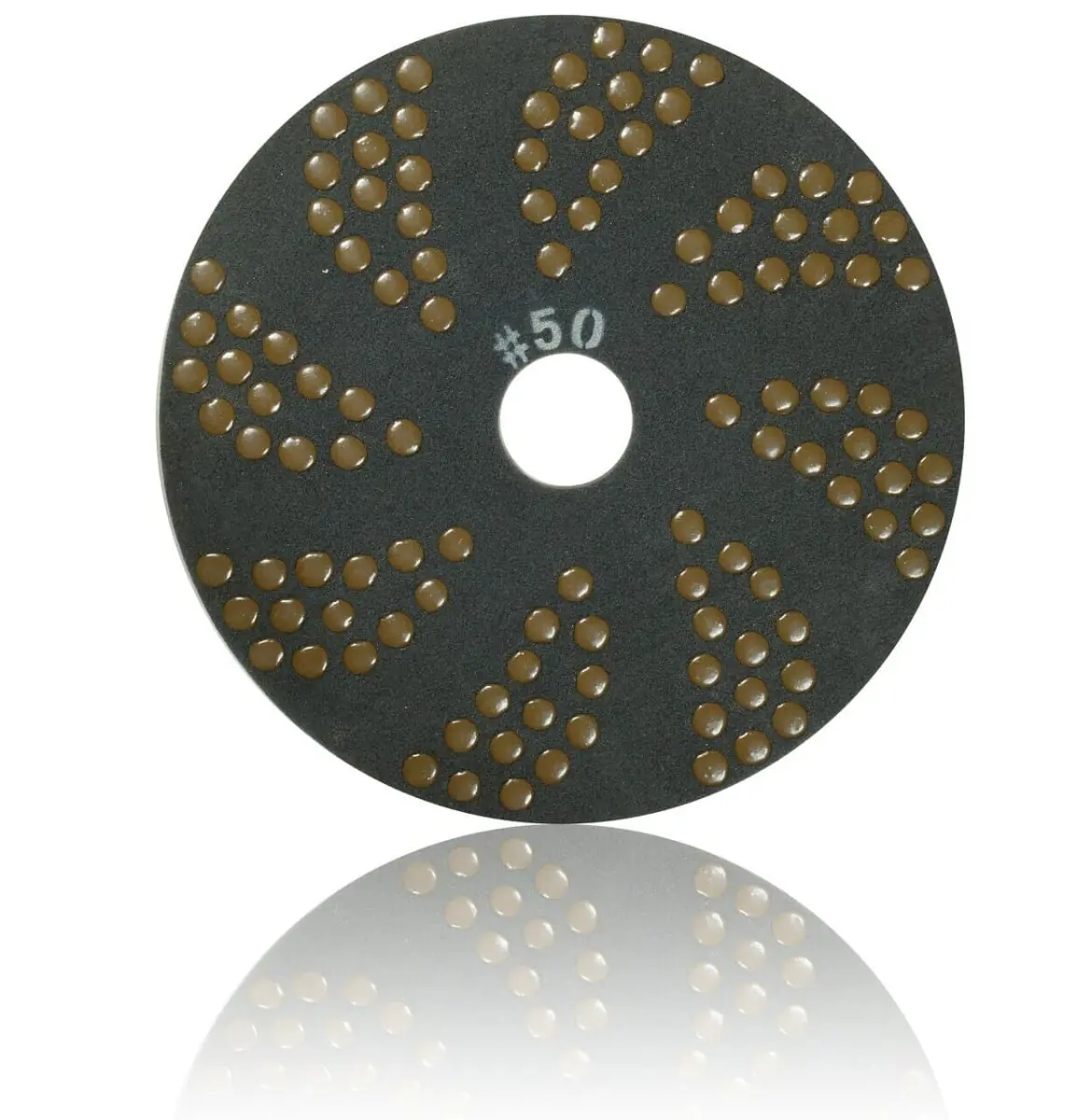

Color Coded:

- 30 Grit – Lt.Blue

- 50 grit – Blue

- 100 Grit – Gray

- 200 grit – Yellow

- 400 grit – White

- 800 grit – Green

- 1500 grit – Red

Description

The V.E.S.P.A. Polishing System has been designed for demand in the concrete polishing market. A Value Engineered Simplified-Polished Application is an economical alternative to traditional concrete polishing when smaller budgets need to be met but a densified/hardened/refined surface is needed for the end result. We have infused our HYBRID metal bond matrix into our diamond encrusted Hurricane pad. The VESPA is designed to use on burnishing/buffing equipment and automatic scrubbers. A Faster cut, faster hone and refined and faster polish is the result. The VESPA is ideal on new, flat concrete. It is designed to open, hone and polish/refine; it is in no way intended to flatten a concrete surface. For older, uneven surfaces, the concrete should be grinded with traditional grinding equipment and tooling in preparation for the VESPA pad to complete the polishing process.

Uses

The V.E.S.P.A. pads may be used wet or dry and are available in 14″, 16″, 18″, 20″ and 27″ diameters with 30, 50, 100, 200, 400, 800 and 1500 grits. The V.E.S.P.A. polishing system will open the surface of flat concrete and hone the surface to properly accept a densifier/hardener and continue to hone and polish to 1500 grit ready for guard/sealer. The smaller grits (30, 50, 100) are ideal for quick mechanical preparation for coatings and overlays. Quickly refurbish/re-polish existing, well-worn, improperly maintained densified/hardened concrete. Many uses within a proper maintenance schedule and ideal on auto-scrubbers.

Application

The V.E.S.P.A. pads have many uses and applications. The entire pad is coated with a diamond powder of the same grit as the infused HYBRID metal bond. The pad can be flipped over and used to as a cleaning or burnishing pad.

Cautions

The Value Engineered Simplified-Polished Application, VESPA Pad is designed to run at low to high speed, 200 to 1500 rpm. Caution should be taken on any surface with control joints, expansion joints, cracks, gouges, holes or deep scratches in the surface. Any height differential from one area of the slab

to another can cause damage to the VESPA. Be certain to walk the entire area and address any differences in height with a hand grinder or floor grinder to level out any differences in slab heights.

Deep gouges or scratches should be filled and leveled to the slab as well or damage can be incurred to the VESPA Pad.

Any nails, screws, anchors, anchoring devices, etc., must be removed or ground to the surface of the slab prior to running the VESA Pad over the surface.

The VESPA Pad is designed to be used wet or dry. When running the VESPA Pad wet, the surface should be saturated and continually kept saturated. The wetter, the better! The heat created with the VESPA Pad on dampened or misted surfaces will quickly turn the slurry into a thickened paste and the paste will gather on the VESPA Pad and can dramatically reduce the VESPA Pads effectiveness. It is recommended to thoroughly clean the pads after each use with water to keep the pad clear of buildup of slurry or dust.

When running the VESPA Pad dry it is recommended to use on a burnishing machine with an active vacuum system. Running the VESPA Pad at the lower grits can create a remarkable amount of dust.

There are several models on the market, both propane and electric.