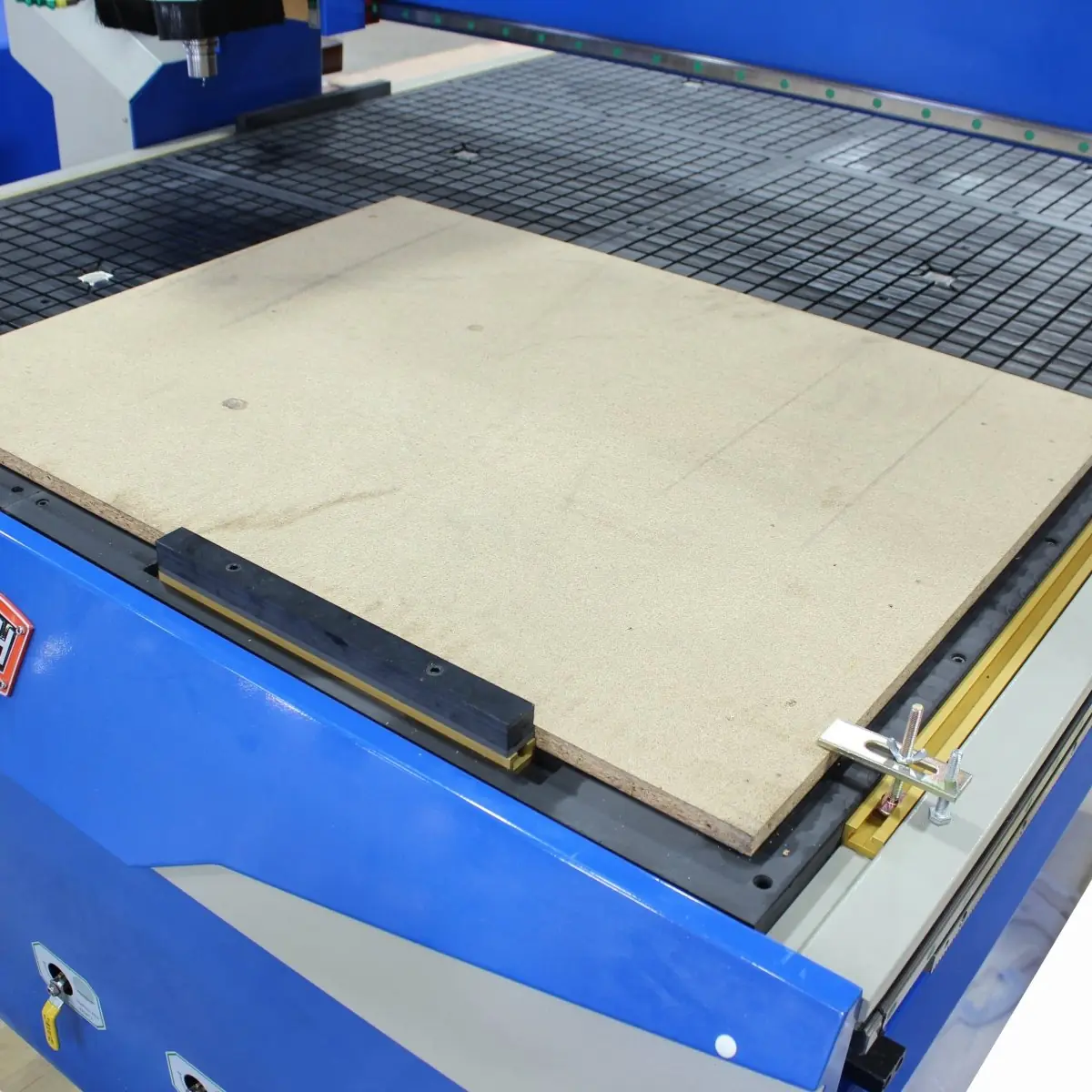

This large CNC router table can automatically change tooling in just 8 seconds. You can program profile switches right into your design to save time and maintain precision during industrial production runs.

- Large 4’ x 8’table.

- Arrives pre-built with correct alignment. No complicated set-up process.

- Comes with software for plotting out designs on your computer, then turning them into cut patterns for the machine.

- Runs on 220-volt 3-phase power.

- Powerful 10hp spindle can tackle hard materials without flinching.

- 7.5 kilowatt air-cooled spindle will stay accurate through years of production.

- Variable spindle speed, from 3000 to 24,000 rpm.

- Servo motors ensure smooth running at both fast and slow speeds.

- High gantry is up and away from material, allowing you to see what it’s doing.

- Y axis moves far enough for the gantry to clear the table. You can take the material directly off; no need slant it awkwardly.

- Upload your design to the table with a USB drive. Automatic tooling changes let you swap out bits with computer-controlled precision. Sensor compensates for the change in tool lengths. That change might seem tiny, but it makes a huge difference to the finished product.

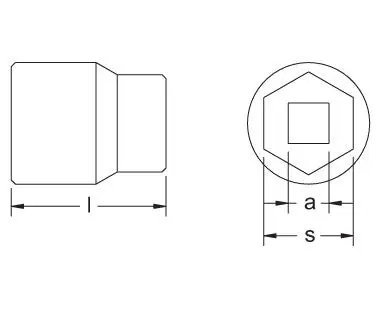

- Pre-load up to 4 collets with your chosen profiles; the router will switch between them as programmed.

-

Powerful 7hp vacuum in the bed of the table holds the material in place during the cutting process.

- 4 vacuum zones allow you to turn on the valve only for the area where you’re working.

- Arrange each zone’s vacuum seal into the shape of the material to provide well-distributed suction.

- Dust shroud fits over the spindle; you can vacuum out all the dust and chips while you’re cutting.

- Fully-welded steel frame keeps the machine stable, helping the router last longer and preventing vibrations from taking the cut off-course.

- Covered by a 1-year parts warranty.

- You can count on lifetime technical support by phone from Baileigh’s team of reps, all with hands-on product experience.

BOBCAD-CAM EXPRESS DESIGN SOFTWARE (INCLUDED)

The WR-84V-ATC comes standard with BobCAD-Cam Express programming software. You can design or plot out your project on any computer and load the table via a USB drive. To learn more or download a free trial, click the BobCAD-Cam logo above.

Specs

| Item Number | WR-84V-ATC |

|---|---|

| Shipping Weight | 4800lbs |

| Actual Working Area | 96.5″ x 50.5″ |

| Speeds | 7 (3,000 – 6,000 – 9,000 – 12,000 – 15,000 – 18,000 – 24,000 rpm) |

| Spindle | Air Cooled |

| Z Axis Stroke | 8″ |

| Maximum Moving Speed (Inches Per Minute) | 394 |

| Maximum Engraving Speed (Inches Per Minute) | 394 |

| Reposition Accuracy | 0.0019 |

| Tool Diameters | 1/8”, 4mm, 6mm, & 12mm |

| Power | 220V Three Phase |

| Length | 132″ |

| Width | 83″ |

| Height | 70″ |

| Horse Power | 10 |

| Weight (lbs) | 4800 |

| Table Style | Vacuum |

| Notes | Applicable Materials – Acrylic, Copper, Aluminum, Wood, PVC, ABS, Insulation Plate, Bakelite Plate, Honeycomb Plate, Resin, Organic Board, Aluminum Composite Panel |

| Shipping Dimensions (Inches) | 144x82x81 |

* specifications subject to change without notice.